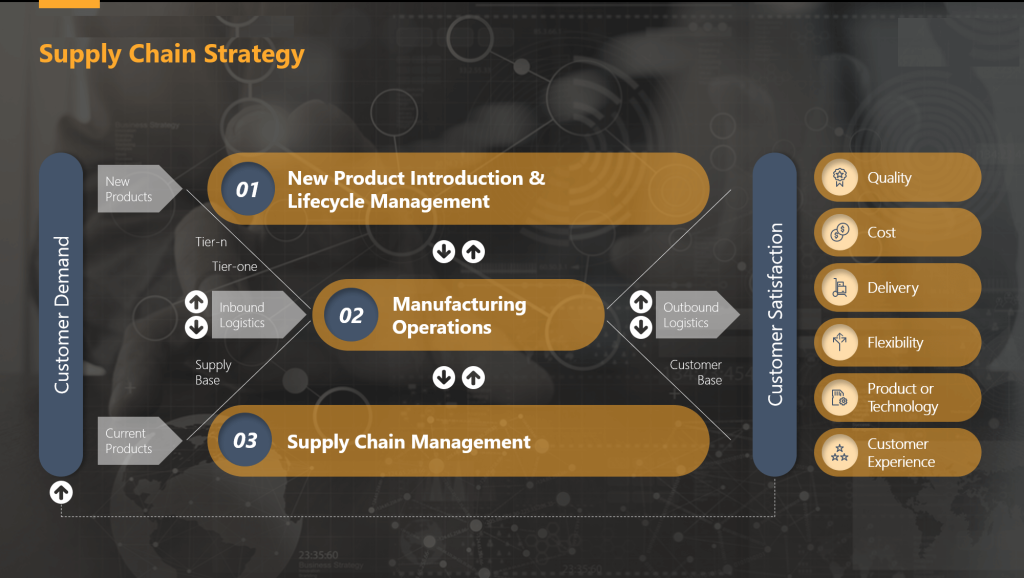

Supply Chain Strategy

Why Your Businesses Need a Strong Supply Chain Strategy and Design

A strong supply chain strategy is the backbone of any successful business. In today’s rapidly changing market, companies must contend with rising costs, supply chain disruptions, and shifting customer demands.

In such scenarios, a robust supply chain strategy and design are impactful solutions for helping businesses stay competitive.

Why do businesses rely on a well-planned supply chain strategy and design? Because it can enhance efficiency, reduce risk, and drive growth.

| Overcoming operational hurdles | Ensuring cost reduction | Gaining a competitive edge |

It is said that 55% of manufacturing businesses prioritize improved supply chain visibility. With these figures, the role of strategic supply chain management, strategy, and design has never been more critical.

If you are one of those businesses with similar goals of traction, efficiency, and improvement, keep reading.

What is Supply Chain Strategy and Design, and How Does It Help You?

Supply chain strategy and design focus on structuring and streamlining the flow of raw materials, information, and resources to optimize production and delivery processes. Often ignored, supply chain strategy and design are critical factors with a significant impact.

Businesses that invest in robust and well-thought-out supply chain strategies are better equipped to handle uncertainties, improve efficiency, and consistently meet customer expectations.

However, only 6% of businesses have achieved full supply chain visibility. The stats highlight the need for more strategic planning and robust and steady supply chains.

Approaches to Supply Chain Strategy

There are two main approaches to supply chain strategy;

| Efficiency-Oriented Supply Chains | Responsiveness-Oriented Supply Chains |

Supply chains based on this approach are suitable for industries with predictable demand and low-cost products. These supply chains focus on minimizing costs and maximizing efficiency. | This approach is ideal for industries with uncertain demand and rapidly changing customer needs. You must know that such supply chains prioritize flexibility and speed. |

Importance of Supply Chain Design Strategy

A strategic supply chain ensures the following:

Cost Efficiency

A well-designed supply chain optimizes resource utilization, improves processes, and minimizes waste, reducing costs. A strategic supply chain ensures efficient logistics and inventory management, essential for reducing costs, directly impacting a company’s bottom line.

Customer Satisfaction

Customer satisfaction is one of the key milestones for any business. 83% of companies prioritize customer experience in their digital supply chain strategies.

A well-structured supply chain ensures timely product delivery and enhances customer satisfaction. This good reputation can go a long way. For instance, companies that meet or exceed customer expectations are more likely to secure repeat business and positive word-of-mouth recommendations.

Ever wonder how companies like Amazon secure big wins every day, particularly in customer service? The system is known for its highly efficient supply chain, which was born after an excellent supply chain strategy and design were implemented.

Risk Management

Supply chain disruptions to geopolitical instability — Businesses often face challenges that require a robust strategy to respond accordingly.

It’s crucial because a strong supply chain strategy and design incorporates risk management strategies, such as supplier diversification, contingency planning, and working side by side to minimize potential disruption in a supply chain network.

For instance, consider pharmaceutical companies. Such businesses keep extra suppliers in the loop to ensure a steady drug supply and reduce the risk associated with shortages.

Flexibility and Agility

A responsive supply chain equips businesses with all the right strategies to respond to adaptations and sudden market fluctuations. This agility enables companies to capitalize on emerging opportunities while effectively navigating unforeseen challenges.

One prime example of a robust supply chain strategy is Zara’s. The brand’s design and strategy allow it to adapt rapidly to changing fashion trends.

Competitive Advantage

An efficient supply chain is a key differentiator in the market. Companies with robust supply chains relying on an outclass strategy and design can offer better products and services at lower prices, giving them a significant edge over competitors.

Target, for example, has integrated AI-driven supply chain optimization. Among other factors, this is a great design that distinguishes Target from its competitors in the market.

Global Reach

An effective supply chain strategy ensures smooth operations across different regions for businesses operating globally. Such a strategy will emphasize managing cross-border logistics, compliance with international regulations, and maintaining consistent quality standards.

Businesses adapting to tariff changes and international trade agreements increasingly focus on diversifying their supply chains to minimize risks.

Strategic Goals in Supply Chain Design

Lately, we’ve been talking about supply chain strategy and design. But what strategic goals combine to make a strong supply chain strategy and design?

Let’s explore these aspects that allow businesses to build robust supply chains that meet their current needs and position them for future growth and success.

Alignment with Business Objectives

The supply chain strategy must align with the overall business goals. For instance, if expanding market share, launching new products, or entering new markets are the goals, your plan must incorporate tactics to achieve these goals.

It’s crucial because businesses with well-integrated supply chain designs can achieve their objectives faster and more efficiently.

Integration and Collaboration

A well-structured supply chain promotes collaboration among suppliers, manufacturers, and distributors—all stakeholders. This can be done through integrated systems and technologies.

No business should overlook this aspect while planning the supply chain strategy and design to ensure seamless communication and coordination while reducing errors.

Continuous Improvement

Supply chains that evolve with the market are considered the best ones. Regularly reviewing and refining supply chain processes ensures they remain efficient and effective. What does it hint towards? This shows that an excellent supply chain design and strategy must have room for continuous improvement. It should be designed to accommodate adopting new technologies, exploring innovative solutions, and learning from past experiences.

Supply Chain Strategy Planning

There are four components of supply chain planning.

| Integration and Departmental Communication | Day-to-Day Operations Management |

| Purchasing | Distribution and Logistics |

Creating a Supply Chain Strategy

To optimize your supply chain design, start by assessing your current processes. Identify areas and separate them into those working well and those requiring improvement.

- Recognize bottlenecks and inefficiencies that impact overall performance.

- Building a supply chain strategy is based on three phases.

Supply Chain Strategy Design

- Define business goals and KPIs.

- Select suppliers and warehouse locations strategically.

- Evaluate tech and automation requirements.

Supply Chain Strategy Planning

- Develop a system to balance supply and demand.

- Ensure inventory availability aligns with customer needs and market conditions.

Supply Chain Strategy Execution

- Manage inventory, warehouses, and order fulfillment efficiently.

- Monitor real-time data to adjust operations and improve performance.

Types of Supply Chain Strategies

Each type of supply chain strategy works for particular needs and market conditions.

1. Lean Just-in-Time (JIT) Supply Chain Strategy

Focuses on minimizing excess inventory levels and waste.

Works ideally for predictable demand and stable production.

One of the prime examples of the Lean JIT supply chain strategy was witnessed in Toyota’s JIT system, which ensured materials arrived exactly when needed.

2. Flexible Supply Chain

- Fit for industries with seasonal demand and rapid product innovation.

- Stresses adaptable manufacturing processes and quick-response logistics.

3. Risk-Adverse Supply Chain

- Focuses on mitigating risks through supplier diversification and buffer inventory.

- Common in industries with high financial risks, such as healthcare and defense.

4. Customer-Centric Supply Chain Strategy

- Prioritizes customers’ needs and preferences.

- Involves customizing products and services to meet specific customer requirements and enhancing the overall customer experience.

5. Resilient Supply Chain Strategy

- Best for businesses operating in volatile environments.

- Build to withstand disruptions and recover quickly from unexpected events.

- Involves identifying potential risks and developing contingency plans.

6. Sustainable Supply Chain Strategy

- It focuses on reducing the environmental impact of supply chain activities.

- Promotes social responsibility.

- Includes practices such as sourcing eco-friendly materials, reducing carbon emissions, and fair labor practices.

7. Global Supply Chain Strategy

- Aims to leverage global resources and responses to markets to achieve a competitive edge.

- Involves managing operations across multiple countries and regions.

- Requires careful coordination of logistics, compliance with international regulations, and management of cultural differences.

Choosing the Right Supply Chain Strategy

Pro Tip: Never ignore your business goals before choosing a supply chain strategy and design. Most businesses adopt a hybrid approach that combines elements of multiple supply chain strategies.

Here are the key influencing factors:

Industry Conditions

Industry conditions play a pivotal role in the determination of the type of appropriate strategy. For example, FMCG companies may prioritize JIT for efficiency, whereas aerospace manufacturers may need a risk-averse approach.

Customer Expectations

Customer satisfaction is a core factor of any supply chain strategy. High customization businesses, such as luxury brands, need flexibility, while standardized product companies will significantly benefit from a lean strategy.

Operational Capacity

Companies with strong logistics networks can implement JIT effectively. However, those with supply constraints must not ignore risk management.

Consultants in Supply Chain Strategy

Many businesses depend on professional consultants to help them develop a robust strategy to optimize their operations. Here’s what a consultation does:

- Identifying inefficiencies in the current supply chain and recommending improvements.

- Designing tailored supply chain models to align with business goals.

- Implementing relevant technology like AI-based forecasting and warehouse automation.

- Developing risk management strategies, such as backup supplier networks.

- Developing techniques to enhance logistics and transportation to lower costs and improve delivery times.

Conclusion

A robust supply chain strategy and design are crucial pillars on which your business’s success depends. Therefore, companies must work on their supply chain design, focusing on supply chain network optimization.

Also, businesses should continuously refine their supply chain strategies to stay agile and resilient against disruptions, prerequisites for long-term growth and profitability.

- Lean Just in time supply chain

- Flexible supply chain

- Risk adverse supply chain

Latest Article & Content

- Plant Inspections and lubrication schedule

- Breakdown maintenance

- Cost reduction programs

- Improving Oee in Business Operations

- Toll Production and Production Outsourcing

- Country and Work Culture in South east Asia

- Discounted Payback period

- Payback Period

- Cycle Time Optimization: How to Boost Production Flow and Output

- Cycle Time vs Takt Time

- The Complete Guide to Lead Time Calculation

- What Are Two Characteristics of Lean Manufacturing?

- Benefits of Lean Manufacturing

- 10 Proven Ways to Reduce Lead Time in Manufacturing

- 7 Real-World Examples of Lean Manufacturing

- How Do You Get Certified In Lean?

- How to Choose Flowchart Symbols: A Complete Guide for Lean Manufacturing Professionals

- What are The 4 Pillars of Lean?