Error Proofing

Error Proofing: A Step Closer to Overall Efficiency

“Defects Are Not Free! Someone Does Them and Gets Paid for Doing Them” Dr Deming

Error-proofing your business strategy is essential to avoid setbacks that drain your resources. What worsens the situation for businesses is paying again for these mistakes in the name of rectifications— in terms of dollars, time, effort, and much more.

Downtime, waste, and customer dissatisfaction are the price businesses pay for these mistakes.

Thankfully, better alternatives and solutions for error prevention exist, such as Error Proofing.

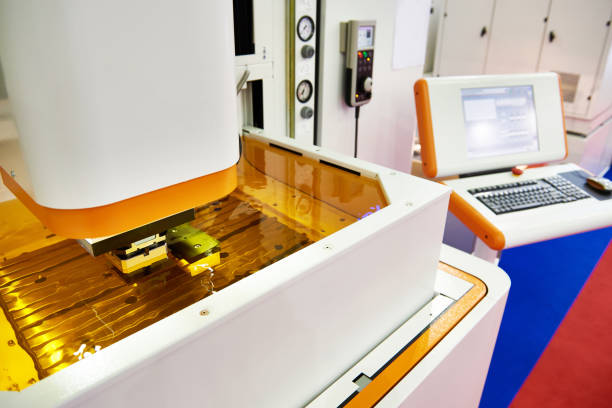

Imagine a Manufacturing Process Where Mistakes Are Impossible or Rare — That’s Error Proofing

Also known as Poka-Yoke(a Japanese term meaning “to avoid mistakes”), Fail Safing, Error Proofing enables businesses to achieve a level where:

- every step of a process runs smoothly

- no manufacturing errors

- no wasted materials

- no need to fix mistakes later

- And in case something happens, it must instantly detect the error

Sounds ideal? That’s the transformation businesses enjoy with error-proofing. Remember it’s not a one-time process that fixes problems but a long-term prevention of mistakes even before they happen again.

What is Error-Proofing? Understanding the Basics

The error-proofing definition describes it as a strategy for creating processes, tools, or systems that make it almost impossible for mistakes to occur.

Even if an error does happen, the system immediately flags it. This indicates the need for immediate correct action before the damage proceeds further.

With this approach, industries have seen massive transformation in terms of designing smarter processes. In return, they save time, money, and resources while delivering better products to their customers.

How Error Proofing might look in action? Consider the example of child-proof caps on medicine bottles. They’re designed exclusively for adults. The design facilitates opening only by adults. This prevents accidental misuse by children. You see, it’s error prevention even before it can happen.

Simple, it’s a powerful approach to keep people safe while solving a common problem in a smart way

Why is Error Proofing So Important? Benefits

Mistakes happen, and that’s natural in a working environment. This particularly becomes more probable where human input is more involved resulting in human error. Even the most skilled workers can slip up.

Well, that’s one side of the coin. Alternatively, such mistakes in industries like manufacturing, healthcare, and services can lead to big problems.

And here’s why we call Error-proofing a game-changer:

- Businesses can save costs because fewer errors with Error Proofing means less wasted material, less rework, and lower costs.

- The improved quality when products are made the finest in the first attempt leads to high levels of boosted customer satisfaction and trust in your organization’s products.

- Increased efficiency is phenomenal! Workers spend less time fixing mistakes and more being productive.

- Fewer errors often contribute to creating safer work environments.

- Brand identity and brand trust grow exponentially when customer satisfaction is better.

How to Implement Error Proofing?

Let’s walk through the steps from start to finish and learn how to implement error-proofing.

- Identify sources of error: Analyze your processes to find where and how errors can occur.

- Create a flow chart: Map out the process and note where human intervention is required.

- Identify potential errors: Consider how the error could happen and the root cause.

- Develop solutions: Consider ways to make the error impossible or to make it easier for users to perform the correct step.

- Implement solutions: Use sensors, warning lights, or other mechanisms to signal problems automatically and a “one path” method to perform a task to avoid errors.

- Monitor and evaluate: Regularly review the process and make adjustments as needed.

Tools for Error Proofing

The following tools can assist with error-proofing a product or process. They help identify the root cause of errors and ensure solutions are implemented smoothly and thoroughly.

It helps organize the causes into categories and establish the relationship between them. | |

Help identify potential causes of defects by asking questions starting with “why.” | |

Failure Mode and Effect Analysis | This helps identify potential causes of defects. |

A technique that automatically interrupts the process when it encounters an error. |

Error Proofing or Poka-Yoke? Same or Different?

Poka-Yoke is another term for Error proofing, but let’s better call it the heart of Error Proofing. Shigeo Shingo, a Japanese industrial engineer who revolutionized manufacturing processes, is the man behind this concept.

So, the idea is simple – Design systems that make it impossible to mess up or instantly catch manufacturing errors and correct them in case they happen.

Real-Life Examples of Error-Proofing

Shape Sorting

Think of how USB plugs are designed to fit only one way. That’s poka-yoke. It prevents you from plugging them in upside down.

Color Coding

Also called visual management, it’s more prominent in hospitals. Different tubes or syringes are color-coded. This avoids mix-ups during procedures.

Interlocks

Have you seen the washing machines that don’t start until the door is fully closed? That’s poka-yoke, which ensures safety and prevents leaks.

Checklists with Visual Aids

- This is a classic poka-yoke tool! Pilots use detailed checklists before takeoff to ensure nothing is missed.

Poka-Yoke: Engineering Perfection for Seamless Operations

Let’s understand the powerful impact poka-yoke can make with the help of a study, where the implementation has reduced the rejection rate to zero.

A study by Rommy Febri Prabowo and Siti Aisyah explores how Poka-Yoke—the Japanese mistake-proofing method—helps manufacturers eliminate errors, cut waste, and improve production efficiency.

Poka-Yoke in Manufacturing

The study reviewed 33 research papers focusing on real-world Poka-Yoke applications in manufacturing industries, including:

- Automotive – Preventing incorrect assembly and misaligned components.

- Electronics – Reducing wiring errors, soldering defects, and part mix-ups.

- Food & Beverage – Avoiding contamination and ensuring accurate labeling.

- Machinery & Equipment – Ensuring correct part placement and reducing rework.

Common Manufacturing Errors Prevented

- Assembly defects – Catching misassembled or missing components.

- Process skips – Ensuring no production steps are overlooked.

- Material mix-ups – Preventing the wrong parts from entering production.

- Operator mistakes – Using guides and fail-safes to minimize human error.

- Equipment malfunctions – Implementing automatic shutdowns for faulty machinery.

Lean Manufacturing Benefits

- Up to 50% defect reduction – Catching errors before they happen.

- 30-60% efficiency gains – Eliminating rework and bottlenecks.

- Lower production costs – Less waste, fewer recalls, and higher profitability.

- Streamlined operations – Smoother workflows with built-in quality control.

- Improved workplace safety – Fail-safes preventing accidents on the factory floor.

Why It Matters

Poka-Yoke isn’t just about catching mistakes: it’s about designing them out. Smarter systems ensure fewer errors, lower costs, and unstoppable efficiency. That’s the power of Lean Manufacturing done right.

Understanding the Scope of Error Proofing Through its Levels

Error proofing works on three levels, each adding more safeguards:

Level 1Detect Errors Before They Happen | Level 2Prevent the Process from Continuing | Level 3Design Errors Out Completely |

Level 1 involves tools or systems that warn workers when they’re about to make a mistake. | This level centers around the situation when an error occurs. Once it’s detected, the process stops until the issue is resolved with the correct action. | This is the ultimate level that stresses the need to design processes so that mistakes can’t happen at all. |

Example: A torque wrench that flashes red if a bolt isn’t tightened correctly. | Example: A machine won’t run unless the safety guards are put in place | Example: Parts that can only fit together when placed correctly. |

Fail Safing, Balancing Automation & Human Involvement

One of the main points here is error-proofing’s immense reliance on automation. Although it’s significant, it still needs to strike a balance through human intervention.

Over-reliance on technology can lead to:

- Skill Atrophy, where workers may lose important skills if everything is automated.

- Reduced Autonomy, where operators may feel less empowered if machines take over.

So, how to strike a balance? Simple — Involving workers in designing error-proofing systems works great. It’s because when the workers understand the purpose of these measures, they’re more likely to embrace them with expertise and in-depth understanding.

Practical Tips for the Fool-Proof Implementation of Error Proofing

Organizations considering foolproofing or error-proofing must consider these tips:

Identify Risk AreasLook at your processes and find where mistakes are most likely to happen. | Involve Your TeamOperators who work on the frontlines often have the best ideas for improving processes. |

Use DataTrack error rates before and after implementing poka-yoke measures to see what works. | Start SimpleBegin with low-cost solutions like:

|

Continuously ImproveReview your processes regularly and make adjustments as needed. | |

Making Error Proofing Effective with Human Input

Error proofing becomes more effective when you view it as an approach that isn’t only about systems and machines but also people. Workers play a significant role in ensuring the processes run smoothly.

Here’s how businesses can make their error-proofing more effective with “Human Touch”:

Train Your Team

Implementation begins from the core! Train your team and help the workers understand why error-proofing is important, what is the benefit to their day to day work. Don’t restrict them. Make them learn its importance by addressing them how error-proofing can be beneficial in the long run.

Develop Skills

Skill development is essential to retain all the good that error-proofing brings in. Offer extensive training programs besides cross-organization training to upskill your workers. This, meanwhile, ensures the reinforcement of best practices.

Review Procedures

This must be done to stay competitive and ahead of your competitors. Regularly update Standard Operating Procedures to reflect changes in processes.

Foster Awareness

This, again is a post-training part, where focus on workers’ mindset is made. Encourage your workers to stay alert and engage in their tasks efficiently to make full use of the poka-yoke

Wrapping it Up: Final Thoughts

Let’s recap! What is error-proofing? Designing and developing systems or procedures that ensure no error occurs or is instantly detected in case it happens.

So, calling out all businesses! Are you ready to take your processes to the next level by making them almost error-free? If yes, start implementing error-proofing lean measures. Do it today to see the difference this approach is capable of making.

Contact us if you have other queries regarding error proofing. Our team of experts are happy to help. Or feel like adding more to our blog? We’re just a click away! Let’s make it value-packed together.

Latest Article & Content

- Plant Inspections and lubrication schedule

- Breakdown maintenance

- Cost reduction programs

- Improving Oee in Business Operations

- Toll Production and Production Outsourcing

- Country and Work Culture in South east Asia

- Discounted Payback period

- Payback Period

- Cycle Time Optimization: How to Boost Production Flow and Output

- Cycle Time vs Takt Time

- The Complete Guide to Lead Time Calculation

- What Are Two Characteristics of Lean Manufacturing?

- Benefits of Lean Manufacturing

- 10 Proven Ways to Reduce Lead Time in Manufacturing

- 7 Real-World Examples of Lean Manufacturing

- How Do You Get Certified In Lean?

- How to Choose Flowchart Symbols: A Complete Guide for Lean Manufacturing Professionals

- What are The 4 Pillars of Lean?