Understanding the Real Difference That Drives Modern Manufacturing

Cycle Time vs Takt Time is really a question of rhythm versus capability, and the answer matters more today than it ever has. Cycle time is how fast your process can work; takt time is how fast your customer needs you to work. Put simply, one describes what you can produce, and the other describes what you must produce to win. The moment these two drift out of sync, your operation starts burning money, morale, and opportunity. In a world of volatile demand, shrinking lead times, and pressure for high-mix agility, understanding the tension between cycle time and takt time is the difference between a factory that reacts and a factory that dominates.

Modern Lean organizations are rediscovering this truth because the landscape has shifted. Customer expectations spike without warning. Batch sizes collapse. Product variants multiply. Every day, operations leaders are trying to match the heartbeat of demand while dealing with constraints that refuse to stay still. That push and pull is exactly why this topic matters today: the companies that master this ratio set the pace for their entire industry.

The Modern Foundation: What These Terms Really Mean

Before diving into the deeper implications, let’s pin down definitions the way real factories use them, not how outdated textbooks oversimplify them.

What Cycle Time Actually Represents

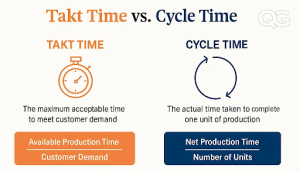

Cycle time is the actual measured time it takes to complete one unit of work at a specific process. It is dictated by reality, not targets. Machine capability, operator skill, fixture design, rework loops, changeover frequency, fatigue, material flow, and even your scheduling rules all shape cycle time. And here’s the catch: cycle time is rarely static. It fluctuates with the real conditions of the shop floor.

Modern plants don’t just measure cycle time; they analyze its behavior under stress. They track how it responds to part variation, how it degrades when tools wear out, how it expands during setup, and how it changes during digital transformation initiatives. Cycle time is both a performance metric and an early warning signal.

Takt Time, the Market’s Metronome

Takt time is the theoretical pace required to meet customer demand based on available production time. It’s not emotional; it doesn’t care about your bottlenecks or your excuses. It simply reflects the truth of your market. When demand changes, takt changes. When your available time shifts, takt shifts. It’s a real-time pulse of the customer’s expectations.

Takt time is the Lean compass. It forces alignment, pulls teams toward flow, and exposes the gaps between ambition and capability. If cycle time reflects the shop floor, takt time reflects the boardroom’s promises. The magic happens when these two numbers meet cleanly.

Why Manufacturers Keep Confusing These Terms

Decades of Lean training have conditioned teams to memorize definitions, yet many still mix the two in daily decision-making. The real confusion comes from ambiguous workflows, outdated metrics, and the pressure to push output regardless of alignment.

When engineers talk takt but measure cycle, systems drift. When supervisors chase the cycle without checking takt, inventory explodes. When leadership demands targets that ignore both, chaos becomes standard operating procedure. Clear thinking is a competitive advantage here.

Misalignment typically shows up in three places: overproduction, bottlenecks, and workforce imbalance.

Overproduction, the Silent Profit Leak

If your cycle time is consistently faster than takt time, you’re producing more than the market needs, creating classic overproduction waste. That sounds noble on the surface, but it’s one of the costliest mistakes in manufacturing. Excess inventory hides problems, ties up cash, clogs material flow, and dilutes focus. Factories convince themselves they’re “running efficiently,” but efficiency without direction is simply waste at scale.

Bottlenecks That Never Quite Go Away

If cycle time is slower than takt time, the bottleneck runs the entire show. That station becomes the villain in every morning meeting, and teams start fighting instead of improving. When the process responsible for the constraint is unclear or constantly shifting, production feels like a guessing game. Aligning cycle time with takt time stabilizes flow and makes bottlenecks visible rather than political.

Workforce Stress and Fatigue

When leaders fail to balance cycle and takt, the people doing the work pay the price. Asking teams to sustain a cycle that is tighter than reality leads to burnout. Letting the system produce too fast leads to frustration when plans change or output is discarded. Humans feel the misalignment long before dashboards do.

The Strategic Layer: Why the Gap Between Cycle Time and Takt Time Determines Competitiveness

Cycle Time vs Takt Time is far more than a process exercise. It shapes cost structure, delivery reliability, workforce morale, automation strategy, and future scalability.

Cost and Inventory Structure

Inventories balloon when cycle time races ahead of takt time. The modern market punishes this. Storage costs rise, carrying costs drain margins, and a single batch recall becomes catastrophically expensive. Companies that synchronize cycle time to takt time carry less waste, freeing cash for innovation and resilience.

Delivery Performance and Customer Trust

When cycle time crawls slower than takt time, delivery reliability collapses. Backorders rise. Customers start shopping for alternatives. Your brand turns from dependable to risky. In sectors like aerospace, automotive, and electronics, this is a reputation you never fully recover from.

Workforce Stability

Balanced systems create predictable workflows. Predictability reduces stress, onboarding friction, and turnover. When teams understand the pace, they adapt with confidence. When the pace is either chaotic or unrealistic, they burn out and leave, taking their knowledge with them.

Automation and Digital Transformation

The smartest automation strategy starts with takt time. You automate only where cycle time must shrink to meet the customer. You avoid automating where flow is healthy. Without this alignment, automation becomes a vanity project rather than a value driver.

Modern factories using connected systems, predictive analytics, and AI-driven work balancing rely on the cycle versus takt correlation as the backbone of their algorithms.

How Real Factories Apply the Concept

It’s easy to talk theory. The real test is whether these concepts survive the noise of production reality. Here’s how actual operations leverage Cycle Time vs Takt Time to make smarter decisions.

Automotive Assembly Lines

Automotive plants live and die by takt time. Every workstation, from stamping to final trim, is designed around a calculated takt rate. Cycle time is monitored relentlessly. If a station’s cycle time drifts even a few seconds past takt, the entire line feels the shock.

Modern high-mix assembly plants use dynamic takt, adjusting every shift based on real demand. Cycle time improvements target the worst-performing stations, not the loudest complaints.

Electronics Manufacturing

PCB assembly lines face massive demand fluctuation. Takt time may change week to week. Here, cycle time improvements often come from reducing changeover, reorganizing feeders, and using inline inspection instead of batch inspection.

The smartest plants treat takt time like a living organism. It grows, shrinks, and evolves with the market. Understanding this keeps them competitive in a world where product life cycles are brutally short.

Heavy Equipment and Industrial Machinery

These factories rarely have the luxury of a fixed takt because products vary wildly. Instead, they use takt planning at a higher level to forecast labor needs, shift patterns, and capacity.

Cycle time studies focus on repeatable elements: welding sequences, machining passes, torque cycles, and testing routines. Matching these studies to projected takt rates builds confidence in future commitments.

High-Mix Low-Volume (HMLV) Shops

This is where confusion peaks. Because takt seems abstract, many HMLV plants ignore it entirely. The reality is, takt time is still essential; it simply shifts from per-unit cadence to per-family cadence.

Cycle time becomes the lever that determines scheduling flexibility and labor allocation. A strong understanding of both gives HMLV leaders the power to quote confidently, commit intelligently, and adapt rapidly.

Tools and Frameworks That Clarify the Relationship

When the pressure rises, intuition isn’t enough. Modern Lean operations use a combination of digital tools and analog frameworks to align cycle time and takt time.

Time Observations and Work Sampling

These uncover the true nature of cycle time: value-added work, non-value-added movement, wait states, tool reach, ergonomic inefficiencies. Real improvement starts on the floor, eyes open, stopwatch in hand.

Standard Work

Once cycle time stabilizes, standard work documents preserve the gains. They become the reference that protects the process from creeping variation and tribal shortcuts.

Heijunka, or Production Leveling

Flattening demand waves makes takt time more predictable. Without leveling, takt becomes a chaotic pulse that drives instability. Leveling turns takt from a threat into a planning asset.

Line Balancing

This ensures no single workstation bears the burden of the entire process. When every station’s cycle time fits the takt envelope, flow becomes smooth instead of heroic.

Digital Twins and Simulation

Modern factories simulate takt-time scenarios months before changeovers. They model how cycle times behave under new mixes, failure modes, and staffing strategies. This is the future of Lean: not guesswork, but predictive precision.

Challenges That Sabotage Alignment

Even with good intentions, alignment between cycle time and takt time is hard to maintain. The biggest obstacles aren’t technical; they’re organizational.

Unstable Processes

Variation destroys flow. If a process can’t consistently hit its cycle time, takt becomes irrelevant. This is why Lean puts so much emphasis on stability and root-cause elimination.

Siloed Decision-Making

When engineering improves cycle time but scheduling ignores takt, or when leadership sets takt without understanding floor capability, the whole system fractures. Alignment requires cross-functional thinking, not isolated victories.

Unreliable Demand Forecasting

Takt time depends heavily on accurate demand signals. The more volatile the forecast, the harder takt becomes to use as a planning anchor. Digital forecasting tools are becoming essential in maintaining sanity here.

Legacy Thinking

Old habits die hard. Some managers still equate speed with success. Others believe takt time only applies to automotive-style production. These mindsets block improvement and keep factories slow, bloated, and reactive.

Bringing Cycle Time and Takt Time Into the Future

Factories are evolving. The competitive landscape rewards companies that treat Cycle Time vs Takt Time like a living, breathing alignment exercise rather than a Lean vocabulary quiz.

AI-driven scheduling tools now analyze cycle time in real time, adjusting staffing, sequencing, and machine assignments to maintain a takt-consistent flow. Wearable sensors track operator motion, revealing seconds of hidden waste. Advanced MES dashboards issue alerts when cycle-time drift threatens takt compliance.

This isn’t science fiction. This is happening today in smart factories that have embraced digital Lean. The future belongs to the manufacturers who use data not just to measure, but to anticipate.

And let’s be honest: in a world of supply chain volatility, precision isn’t optional anymore. It’s survival.

The Executive Perspective

For executives, Cycle Time vs Takt Time isn’t just a Lean conversation. It’s a strategic one. It affects profitability, capital planning, workforce design, customer retention, and competitive positioning. Leaders who insist on aligning these two metrics bring clarity to their operations. Leaders who ignore them drift into firefighting and reactive chaos.

The smartest executives use takt time as a contract with the market and cycle time as a contract with the factory. When the two contracts align, sustainable growth becomes real.

The Shop-Floor Perspective

Supervisors and operators feel the truth of this relationship every day. They know when the pace is unreasonable. They know when the system is producing just to “look busy.” They know when the process isn’t stable enough to match takt. Listening to them is often the fastest path to alignment.

Cycle time improvements that don’t involve operators fail quickly. Takt time changes that don’t involve supervisors cause chaos. Alignment becomes a shared responsibility, not a spreadsheet.

The Consultant and Engineer’s Perspective

Lean consultants and industrial engineers live in the numbers, but they also know the hidden traps. They understand how easily cycle time can be mismeasured, how easily takt time can be misinterpreted, and how quickly management enthusiasm can outpace capability.

Their role is not just analysis, but translation. They bridge leadership’s ambition with the floor’s reality. They bring discipline to process improvement and clarity to demand-driven planning.

The Bold Truth Moving Forward

The companies that master Cycle Time vs Takt Time are the companies that win the next decade of manufacturing. They build factories that think, react, and adapt with precision. They eliminate the friction between capability and demand. They create workplaces where teams trust the pace and trust the plan. They operate with urgency, but not chaos. Discipline, not panic. Flow, not firefighting.

Here’s the truth. Manufacturing has entered an era where speed without alignment is dangerous, complexity without clarity is expensive, and output without purpose is pure waste. If you want a competitive edge, start with this simple question: Does your cycle time support your takt time? The factories that answer yes are defining the future. The factories that answer no are already falling behind.

This is your moment to align, recalibrate, and move forward with intention.