Bill of materials (BOM)

Bill of materials (BOM)

Manufacturing problems in businesses are common and usually involve the unavailability of raw materials and parts throughout the production process.

The good part, however, is that you can solve real manufacturing challenges with a bill of Materials(BOM) for every good you produce.

Before we discuss the details, here’s a question.

Have you ever faced the following situation in your business?

Your production line suddenly grinds to a halt. Why? You’ve run out of a critical component. Meanwhile, your procurement team rushes orders at premium prices to resume production. Amid all this chaos, your delivery deadlines loom, and customers grow impatient.

Or you might have discovered quality issues in shipped products, maybe, because an incorrect part was substituted during assembly with no documentation.

No? Then perhaps you are struggling with inventory management — overstocked on some components while continuously short on others.

These and other similar manufacturing nightmares affect businesses of all sizes. And they all share a common solution: a well-structured BOM or bill of materials.

A comprehensive BOM serves as the ultimate authentic source for manufacturing operations.

- It prevents production bottlenecks by ensuring all necessary components are identified and procured before assembly starts.

- It safeguards product quality by standardizing component specifications and assembly procedures.

- It optimizes inventory management by allowing it to be used for accurate forecasts of material requirements for any production run.

- It also helps quickly trace problems to their source in case an issue arises, minimizing downtime and customer impact.

What Is a Bill of Materials (BOM)? Understanding the Basics

BOM stands for Bill of Materials. It lists all the raw materials, components, sub-assemblies, and instructions needed for the construction, manufacturing, or repair of a product or service.

BOM is a detailed recipe that guides manufacturing teams throughout the production process and ensures consistency and quality in every product.

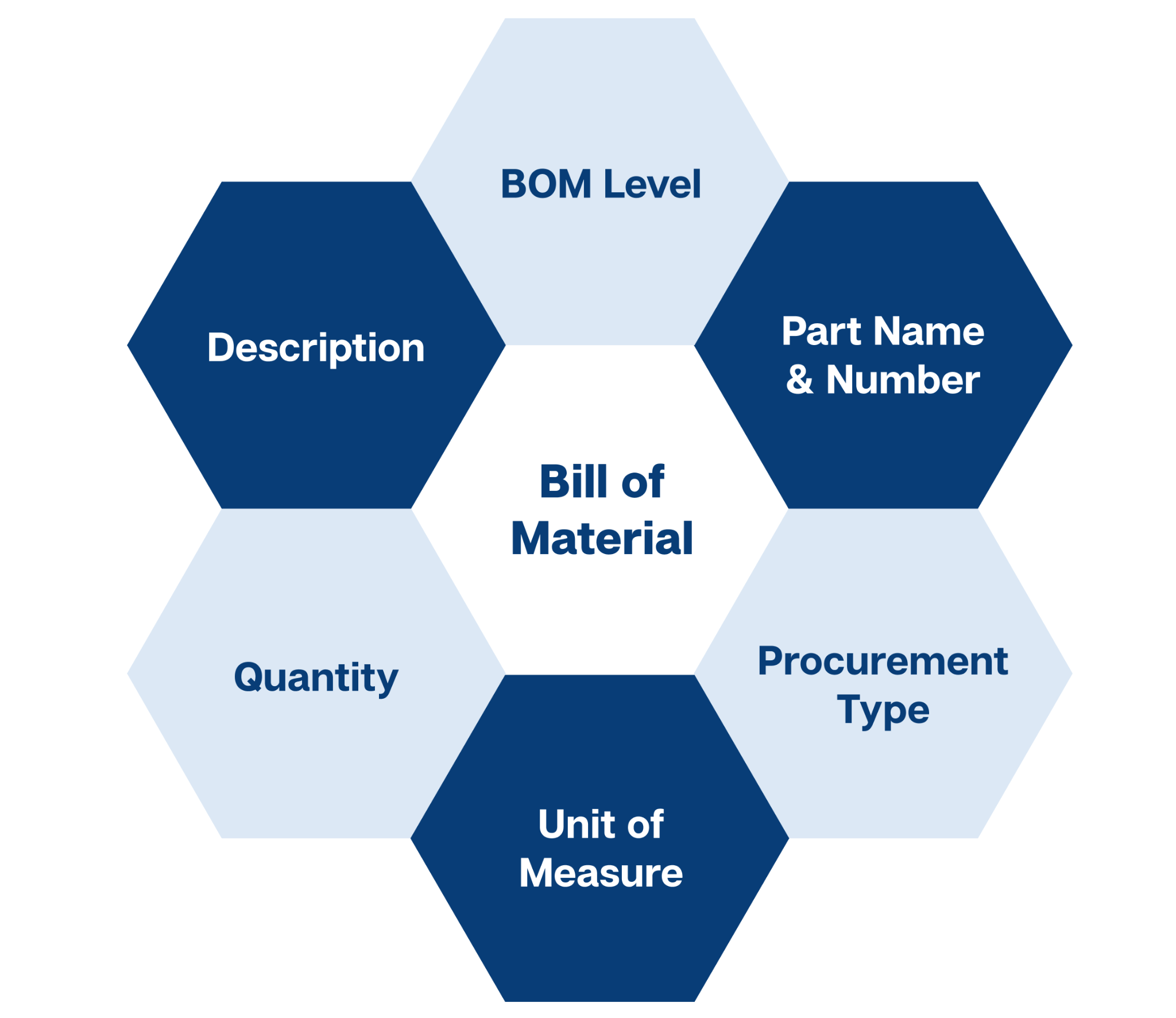

BOM includes the following crucial information:

| Part names and numbers | Specifications (size, weight, dimensions) |

| Description of each component | Alternative and substitute parts |

| Quantity and units of measure for each part | Manufacturing instructions |

Part revisions | |

A BOM typically presents the finished product at the top, followed by a hierarchical breakdown of individual components and materials.

This structured document ensures that manufacturing teams have all the information they need to procure the right materials and assemble the product precisely.

Why BOMs Matter in Manufacturing

In Lean manufacturing, we focus on reducing waste and improving efficiency, and a good Bill of Materials (BOM) plays a huge role in that. It’s easy to overlook, but when your BOM is well-structured, it can solve a lot of common production issues. Here’s how:

1. Material Shortages and Production Delays

There’s nothing worse than getting into the middle of a job and realizing you’re missing a part. This happens a lot in manufacturing. When your BOM is clear, it helps you catch these gaps early. You can make sure every part is accounted for before you even start production, avoiding delays that slow you down.

2. Inconsistent Product Quality

If everyone’s working from a different set of instructions or specifications, it’s no surprise that quality can vary. This can be a real problem. A BOM ensures that all teams are on the same page, using the same parts and the same process every time. It’s a simple way to ensure that your product quality stays consistent across all runs.

3. Cost Overruns

Ordering parts last minute or buying too much of something is wasteful, both in time and money. A detailed BOM helps you avoid this by allowing you to plan accurately. You can accurately forecast your material needs, which means fewer surprise orders and a more efficient production process. It keeps your costs in check and your inventory lean.

4. Supply Chain Vulnerabilities

Supply chain problems are inevitable at some point, but they don’t have to shut you down. When you have a correctly defined BOM that shows all your key parts and where they’re coming from, you can spot potential weak points in your supply chain before they become a problem. It helps you plan for backups and manage risks proactively.

5. Inefficient Troubleshooting

When something goes wrong, you want to solve it quickly. But if you don’t have a clear picture of every part in your product, troubleshooting can feel like guesswork. A good BOM helps you get to the bottom of issues fast. You can track down which part or process caused the problem and fix it, cutting down on downtime and making your operation run smoother.

Types of BOM in Manufacturing

Different manufacturing backgrounds require various types of BOMs. Manufacturers need to learn and understand these variations and choose the right approach to address their specific needs.

1. Engineering BOM (EBOM)

An engineering BOM ensures that all the necessary items, parts, components, subassemblies, and assemblies are captured in the engineering design. Typically created during the product development phase, this type of BOM defines the design of a finished product. It’s commonly based on CAD drawings and focuses on the functional sides of the product and its many components.

Key characteristics:

| Created by product engineers |

| Based on CAD or electronic design automation |

| May undergo multiple revisions during the design process |

2. Manufacturing BOM (MBOM)

Listing all assemblies, parts, and materials required to complete the manufacturing process, this type of BOM is organized according to the assembly sequence. It includes information about how components relate to one another during production.

Key characteristics:

✔️Used directly in the production process, live production

✔️Includes packaging materials

✔️Essential for enterprise resource planning (ERP) and materials requirement planning (MRP)

3. Sales BOM (SBOM)

This type of BOM is used during the sales stage to define product details before assembly. It’s useful for configurable products with multiple options or variations.

Key characteristics:

| Shows how products are sold rather than built |

| Useful for customizable products |

| Helps sales teams understand product configurations |

4. Configurable BOM

A Configurable BOM allows for flexible assembly (based on customer requirements) for products that can be customized (like computers or automobiles).

Key characteristics:

✔️Favors product customization

✔️Includes rules for valid configurations

✔️Adapts to customer specifications

5. Multi-Level Bill of Materials

A Multi-Level BOM shows hierarchical relationships between:

- Components

- Sub-assemblies

- Final product

By providing greater detail than a single-level BOM, a multi-level BOM proves to be more valuable for complex products with multiple assembly stages. This type of BOM is common in vehicle manufacturing, including the aerospace industry.

Key characteristics:

➡️Shows parent-child relationships between components

➡️Used for complex products with numerous components

Quantity and Units of Measure in BOMs

Accurate quantities and units of measure in a functional BOM are crucial.

Quantity

The quantity field specifies how many of each component are needed to build one unit of the parent item.

For instance, a bicycle BOM might indicate that four spokes are needed for each wheel, while two wheels are required for each bicycle.

Units of Measure

Units of measure define how components are quantified.

Common units include:

| Count (ea, pcs) for discrete items | Volume (L, gal) for liquids |

| Length (m, ft) for linear materials | Area (m², ft²) for sheet materials |

Weight (kg, lb) for materials sold by weight | |

Explosion vs. Implosion

Information in BOMs can be represented in two different ways, each offering a unique perspective on the product structure.

Explosion Display (Top-Down) | Implosion Display (Bottom-Up) |

|---|---|

Example: |

Example: |

How to Make a BOM: A Step-by-Step Guide

Discover the step-by-step approach to creating an effective BOM.

Pro Tip: It’s a time-consuming process since crafting a BOM requires careful planning and attention to detail.

1. Determine Required Data

Begin by identifying what information needs to be included in your BOM. This typically includes:

Start by identifying what info needs to be included in your BOM. Typically, it includes:

- Parts names, codes, and numbers

- Descriptions

- Quantities and units of measure

- Specifications

- Procurement information

2. Select BOM Structure

Assess which BOM – a single-level or multilevel is more appropriate for your product. If you deal in complex products with multiple assemblies, a multi-level BOM must be preferred.

3. List Components

Begin with the finished product at the tip and further break it down into its major assemblies. Next, list all the components required for each assembly.

4. Add Detailed Information

Include the following for each component:

- Part name and number

- Description

- Procurement type(buy, make, subcontract)

- Quantity and unit of measure

- Specifications (materials, dimensions, etc.)

- Alternative parts (if applicable)

5. Review and Validate

Let the engineering and manufacturing teams review the BOM since it’s crucial for ensuring accuracy and completeness. Check for missing components, incorrect quantities, or unclear specifications.

6. Integrate with Systems

Connect your Bill of Materials with relevant systems such as ERP, MRP, or PLM. This step significantly streamlines procurement, production planning, and inventory management.

7. Establish Revision Control

Implement a system that can track and manage BOM revisions. This ensures that all

Bill of Materials Example

Here’s a practical example to illustrate how a BOM works in manufacturing a product.

Single-Level BOM Example (Chair)

| Level | Part No. | Description | Quantity | Unit of Measure | Specifications |

| 0 | CH-001 | Wooden Chair | 1 | ea | Finished product |

| 1 | LEG-100 | Chair Leg | 4 | ea | Oak, 18’’ length |

| 1 | SEAT-200 | Chair Seat | 1 | ea | Oak, 16’’x16’’ |

| 1 | Back-300 | Chair Back | 1 | ea | Oak, 16’’x20 |

| 1 | SCREW-001 | Wood Screw | 12 | ea | Stainless, 2’’ length |

| 1 | GLUE-100 | Wood Glue | 50 | ml | waterproof |

| 1 | FINISH-200 | Wood Finish | 100 | ml | Matte clear coat |

Multi-Level Bill of Materials Example (Chair)

| Level | Part No. | Description | Quantity | Unit of Measure | Parent Item |

| 0 | CH-001 | Wooden chair | 1 | ea | – |

| 1 | ASSY-100 | Seat assembly | 1 | ea | CH-001 |

| 2 | SEAT-200 | Chair seat | 1 | ea | ASSY-100 |

| 2 | LEG-100 | Chair leg | 4 | ea | ASSY-100 |

| 2 | SCREW-001 | Wood screw | 8 | ea | ASSY-100 |

| 2 | GLUE-100 | Wood glue | 30 | ml | ASSY-100 |

| 1 | ASSY-200 | Back assembly | 1 | ea | CH-001 |

| 2 | BACK-300 | Chair back | 1 | ea | ASSY-200 |

| 2 | SCREW-001 | Wood screw | 4 | ea | ASSy-200 |

| 2 | GLUE-100 | Wood glue | 20 | ml | ASSY-200 |

| 1 | FINISH-200 | Wood finish | 100 | ml | CH-001 |

This multi-level structure provides a clearer picture of how the chair is assembled, with a clear representation of two main sub-assemblies (with their components) – seat and back.

Manufacturing BOMs in the Production Process

The manufacturing BOM plays a critical role throughout the production process. It serves as a guide for procurement, assembly, quality control, and cost management.

Material Procurement

Purchasing teams use the manufacturing BOM to:

With BOM, the purchasing teams can confidently:

- Identify all required materials

- Determine order quantities

- Select suppliers

- Schedule deliveries to streamline production timelines

Production Planning

Production planners rely on the manufacturing BOM to:

- Sequence assembly operations

- Allocate resources and equipment

- Schedule production runs

- Estimate production times

Assembly Process

Workers on the production floor use the manufacturing BOM to:

- Verify that they have all the necessary components

- Follow the correct assembly sequence

- Ensure proper component installation

- Maintain quality standards

Quality Control

Quality control teams use the manufacturing BOM as a reference to:

- Verify material specifications

- Check component fitment

- Ensure all necessary and required parts are included

- Validate final product assembly

Cost Management

The manufacturing BOM in finance departments helps experts to:

- Calculate product costs

- Track material usage, including scrap and waste

- Identify cost-saving opportunities

- Manage inventory investment

Final Thoughts

A well-structured Bill of Materials (BOM) serves as a foundation for efficient manufacturing operations.

It remains one of the most powerful tools that ensures production efficiency, quality, and cost control for both simple products and complex assemblies.

Don’t forget, your manufacturing process is flawless if the foundation is strong, and in your case, it’s the Bill of Materials.

We’re Eager to Hear From You!

What’s your take on the Bill of Materials(BOM)? Share your valuable stance on BOM by writing to us on our page dedicated to experts like you.

Let’s connect and exchange information that might benefit many.

Latest Article & Content

- Plant Inspections and lubrication schedule

- Breakdown maintenance

- Cost reduction programs

- Improving Oee in Business Operations

- Toll Production and Production Outsourcing

- Country and Work Culture in South east Asia

- Discounted Payback period

- Payback Period

- Cycle Time Optimization: How to Boost Production Flow and Output

- Cycle Time vs Takt Time

- The Complete Guide to Lead Time Calculation

- What Are Two Characteristics of Lean Manufacturing?

- Benefits of Lean Manufacturing

- 10 Proven Ways to Reduce Lead Time in Manufacturing

- 7 Real-World Examples of Lean Manufacturing

- How Do You Get Certified In Lean?

- How to Choose Flowchart Symbols: A Complete Guide for Lean Manufacturing Professionals

- What are The 4 Pillars of Lean?